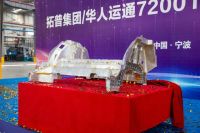

Suzhou AODE Precise Equipment Co., Ltd. and Ningbo Tuopu Group Co., Ltd. will carry out technical exchanges on the die casting temperature control system of 7200T large automotive structural parts in June 2021. Cooperation will be reached in September 2021 and delivery will be made in January 2022. The length and width of the ultra-large structural parts produced by the 7200T die casting machine are nearly 1700mm and 1500mm respectively. It is also the largest integrated aluminum alloy die casting known in the automotive parts field, achieving a weight reduction effect of 15%~20%.

Today, based on the integration of large auto molding and technical difficulties, put forward higher requirements on balance of mold temperature, mold temperature control become rigid demand, oda based on recent 20 years with car/aviation/military/communication in close contact, die casting market, according to the temperature control of large automotive die-casting molding structure integration demand, research and development design a systemic solution, And launched a series of high temperature, medium temperature, low temperature temperature control products (200℃ water temperature machine, 320℃ oil temperature machine, cold and hot temperature control station, multi-channel mold cooler, multi-channel point cooler, integrated control system) for matching the "integrated die-casting of large auto die-casting structural parts".

Very large automobile die casting structure process is long and thin wall, so requires mold temperature have during the long process, according to the different flow accurately control the temperature of different die area, so the width of the mold temperature control in with known and unknown requirements, therefore, oda on this basis, the past design experience, design of 20 ℃ ~ 320 ℃ temperature range of big width, At the same time, the large temperature output can not only control the temperature balance of the mold, but also extend to the temperature control of the pressure chamber, punch, shunt cone, gate sleeve and so on. Therefore, the site die casting product technician-enough room for operation.

Intelligent integrated control mode of mold temperature central integrated control management is the inevitable trend of large and super large die casting machine production management, applied to 5000T, 6000T, 7200T, 8000T, 9000T/12000T requires a large number of mold temperature control equipment, temperature control temperature output point is several times the actual number of machines. Single control increases greatly process commissioning work, is not conducive to production quickly, so need to all temperature control equipment for centralized control, the control system consists of a single set, such as temperature, flow, pressure monitoring and data collection, realize the digital management, configuration control system according to different casting requirements at the same time, convenient to increase or decrease in temperature control equipment such as oil, water, point, and the adjustment of temperature/flow/pressure data in the production of the rapid optimization of the mold temperature area.

AODE in early 2020, should be customer requirements to develop large-scale integrated die casting for automotive structural parts of intelligent temperature control system, after more than a year of marketing, have been five well-known at home and abroad new energy automobile enterprises and downstream enterprise recognition and new energy automobile parts purchasing, 4 sets of the consign is used, there are still four sets of production in succession in 2022.