As A subsidiary of a central state-owned enterprise, Customer A focuses on the research and development, production and sales of OLED front-end materials. Its products cover pre-sublimation materials for light-emitting layers, pre-sublimation materials for general-purpose layers, OLED intermediates, etc. The microchannel reactor is one of the key equipment in its production process.

Microchannel reactors have extremely high requirements for temperature control. They need to achieve precise temperature control over a wide range and be able to adapt to complex environments. As a cooperative project recommended by an old customer of AODE, the customer is particularly concerned about the quality of the equipment, the details of acceptance and the long-term stability.

{Solution Exploration and Implementation}

Pain point

Strict quality control: Customers attach great importance to product quality. The synthesis of OLED materials is sensitive to temperature fluctuations and has extremely high requirements for the precision and stability of production equipment. Traditional temperature control equipment is difficult to meet the strict demand of microchannel reactors for precise temperature control within ±1℃.

Complex working conditions: The chemical production environment is complex and changeable. The working environment temperature may fluctuate between 2℃ and +40℃, the relative humidity is 50%-80%, and the temperature difference changes by ±4℃/h. This requires temperature control equipment to have strong environmental adaptability and reliability.

Safety risk challenges: During the reaction process of chemical materials, temperature loss of control may cause safety hazards. Temperature control equipment needs to have explosion-proof and other safety features; otherwise, it may lead to safety accidents and cause huge losses to the enterprise.

{Highlights of the Solution}

Air-cooled hot and cold integrated machine

AODE provided it with a customized air-cooled hot and cold integrated machine. This equipment has the following features to meet the customer's needs:

Part1 Precise temperature control

Adopting PID ±1℃ control technology and paired with high-precision thermal resistance temperature sensors, it can effectively eliminate temperature differences, achieve rapid temperature rise and drop, and meet the demand for rapid temperature switching at different stages in chemical production.

Part2 Wide temperature range coverage

Seamless switching within the range of -30℃ to 200℃, with a built-in 50L oil tank, meeting the demands of continuous production.

Part3 Strong adaptability to the environment

The air-cooled design avoids the risk of freezing and scaling in the water-cooling system. The equipment can operate continuously and stably under working environment conditions with a temperature range of 2℃ to +40℃, a relative humidity of 50% to 80%, and a temperature difference of ±4℃/h, unaffected by environmental changes, ensuring the continuity and stability of production.

Part4 Comprehensive security protection

The heating system is equipped with over-temperature protection, reverse phase protection, motor overload protection, medium shortage protection, pipeline blockage protection, abnormal pressure protection, exhaust protection, etc. The cooling system is equipped with reverse phase, motor overload, high and low pressure of the compressor, anti-freezing, liquid level protection, etc., effectively preventing equipment failure and safety accidents, and providing reliable support for chemical production.

Part5 Intelligent operation

It adopts the PLC+ human-machine interface control mode and is equipped with an explosion-proof mouse. The operation is simple and intuitive, facilitating the staff to monitor the equipment operation status in real time and adjust parameters, thereby improving the efficiency of production management.

{AODE Advantage}

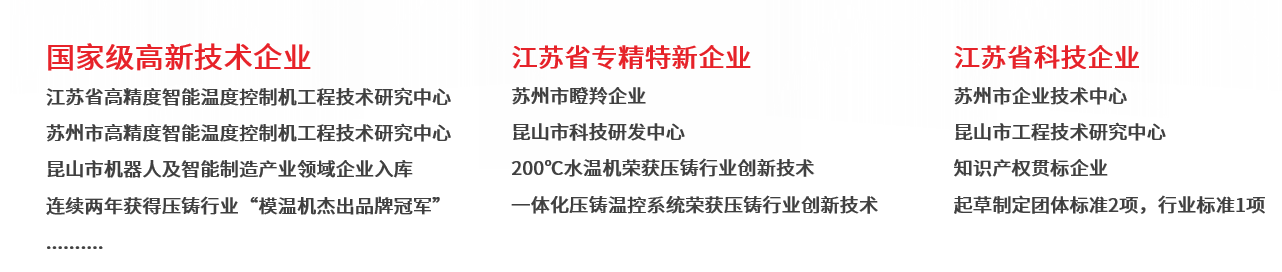

Strong technical strength: AODE has profound technical accumulation and R&D capabilities in the field of temperature control equipment. The air-cooled cold and hot integrated machine adopts advanced control technology and high-performance components, ensuring that the accuracy, stability and reliability of the equipment are at the leading level in the industry, and can provide high-quality temperature control solutions for chemical enterprises.

Outstanding product quality: The products undergo strict quality inspection and testing, meeting the high safety and performance standards of the chemical industry and other sectors. Under complex chemical working conditions, it can still maintain long-term stable operation, reduce equipment failures and maintenance costs, improve the continuity and efficiency of production, and bring significant economic benefits to enterprises.

Customized services: AODE can provide personalized customized services based on the process requirements and on-site working conditions of different customers, ensuring a perfect match between equipment and production processes, meeting the production requirements of enterprises to the greatest extent, and enhancing the competitiveness of enterprises in the chemical market.

Good brand image and reputation: As a professional manufacturer of mold temperature control machines and water-cooled chillers, AODE has established a good brand image in the chemical and other industries with its high-quality products and services, and has won the trust and recognition of many customers. Customer A was recommended by an old customer to choose AODE, which fully demonstrates our good reputation and influence in the industry.