Temperature control solutions for the die-casting industry

Recently, two sets of 9800T super-large integrated die-casting temperature control island solutions provided by AODE for customers have been put into operation. We also extend our warm congratulations on the grand opening of the customer's die-casting production base! Chairman Zhou Dingshan of Suzhou AODE Precise Equipment Co., Ltd. was also present at the opening ceremony to witness this historic moment.

Wide temperature control range from 20℃ to 320℃

Integrated design and centralized management provide a stable and controllable temperature source output.

Customized solution

The commissioning of this die-casting base is a microcosm of the advancement of China's die-casting industry towards higher-end, greener and more intelligent levels. As a newly-built advanced intelligent factory, it has established a full-process digital ecosystem. From the intelligent upgrade of the casting process to the intelligent empowerment of the entire chain, intelligent die-casting runs through every aspect of the production process.

As a leading brand in the industry, AODE also continuously breaks new ground in industry technology. From 6000T to 16000T ultra-large integrated die-casting temperature control, and the new generation of waste heat recovery type temperature control island, from high and low temperature equipment to mold cooling stations, mold temperature integrated control systems, infrared detection systems, and to the IoT cloud platform, AODE constantly meets customer needs and ensures stable temperature control during the production process.

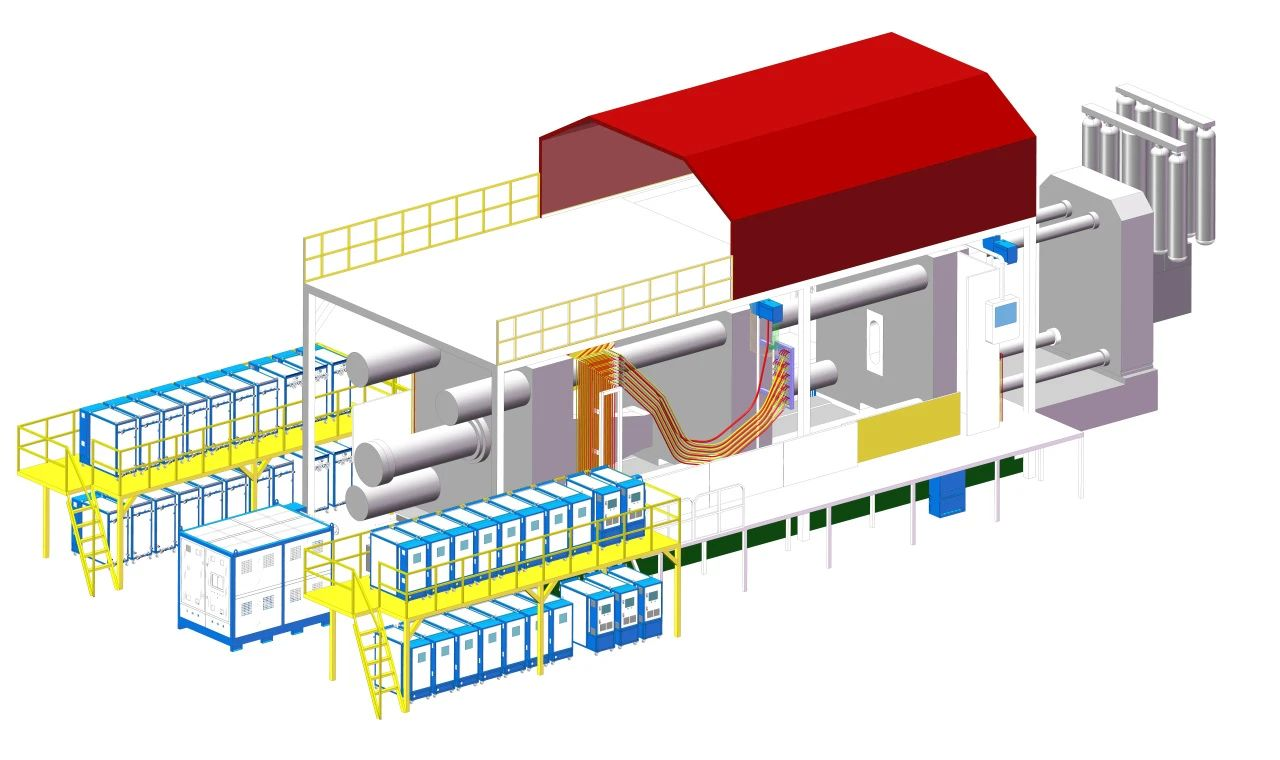

The AODE 9800T ultra-large integrated die-casting temperature control island solution includes a 320℃ high-temperature oil temperature machine, a 180℃ high-temperature multi-channel water temperature machine, a mold cooling station, a pure water system, and a centralized control system. The wide temperature range of 20℃ to 320℃ for temperature control process adjustment enables precise control of the thermal balance of the integrated die-casting mold.

Among them, the oil temperature machine, water temperature machine, and multi-channel water temperature machine adopt a dual-loop design. Each machine can simultaneously connect to multiple mold flow channels. Each branch can choose intermittent water/oil flow control. The temperature control range can be effectively configured to independently display the flow, temperature, pressure, etc. of each branch as monitoring parameters.

Integrated design and centralized management can effectively reduce the number of temperature control devices, lower the installation power of the die-casting island and the requirements for public utilities, save space, and reduce equipment investment and pipeline installation costs.

With the launch of this project, the AODE 9800T integrated die-casting temperature control island provides a stable and controllable temperature source output for the mold temperature balance, ensuring the quality of each die-cast part. It also significantly shortens the production cycle of each mold, reduces energy consumption and installation power, decreases the floor space occupied by the temperature control equipment, and meets the intelligent production requirements of the project. This helps to extend the industrial value in the automotive lightweighting field, expand the scale effect, and enhance the core competitiveness.

At present, the AODE integrated die-casting temperature control system market share is far ahead. In the future, AODE will always adhere to the corporate philosophy of "innovation, quality, integrity, service, and focus", and with more advanced technologies, higher-quality products and services, it will help the die-casting industry achieve more efficient, intelligent and green development, create more value for global automotive manufacturing and other die-casting application industries, and promote the vigorous progress of the entire industry.